Projekt DBU

| E-Mail: | richter@ifw.uni-hannover.de |

| Year: | 2018 |

| Date: | 05-03-18 |

| Funding: | DBU (Deusche Bundesstiftung Umwelt) |

| Duration: | 0416 - 09/18 |

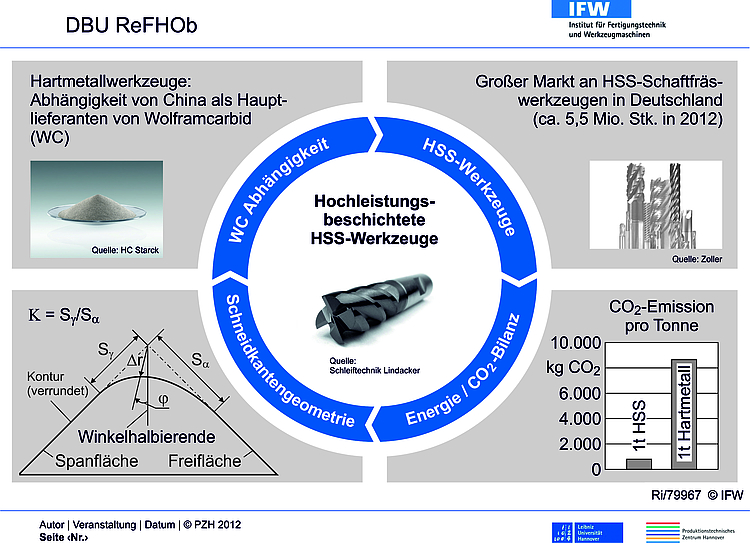

More than 90 % of the metalworking cutting tools are made of solid carbide or high speed steel (HSS). The production and processing of solid carbide tools requires significantly more energy and resources than HSS tools. Coating systems and microstructuring processes of the cutting edges (rounding) were recognized as essential approaches for improving the performance. The existing optimization processes for solid carbide tools are potentially transferable to HSS tools. The objective is to increase the tool life of HSS cutting tools by a factor of 1.6 (about 60 %) in order to achieve ecological and economic improvements in metalworking. Overall, the optimized HSS tools can deliver approximately 4,000 t of CO2 per year.