Systematic investigation of the grinding and dressing process of PCBN cutting inserts

| E-Mail: | mueller-cramm@ifw.uni-hannover.de |

| Year: | 2018 |

| Date: | 15-03-18 |

| Funding: | DFG |

| Duration: | 03/17 – 02/2019 |

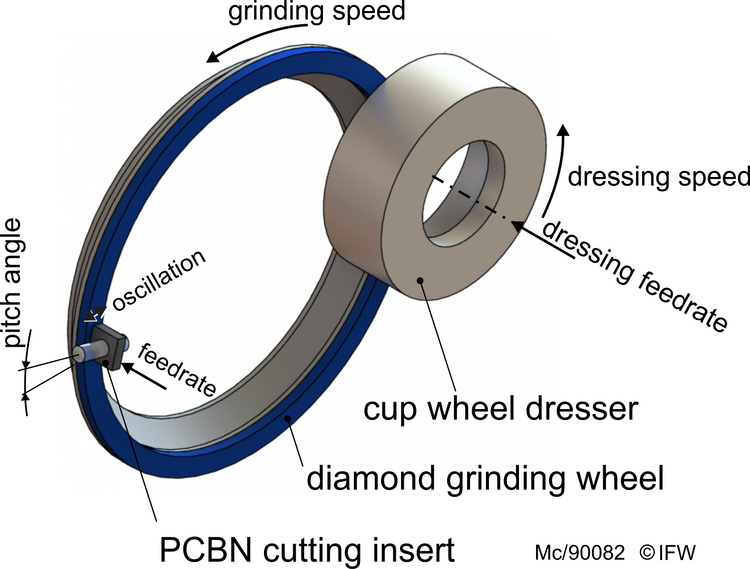

PCBN cutting inserts have a high potential as tools in geometrically determined machining. The cutting inserts are brought to their final dimensions by grinding. Due to the high hardness of the material, wear of the grinding tool can be reduced, but not prevented. Wear mechanisms such as clogging or grain flattening continue to occur. Dressing the grinding wheel in the process, an oscillating movement of the insert and the change of the angle of the workpiece adjustment are suitable strategies to increase both the productivity and the process reliability of this grinding process. However, at the present time, there is a lack of understanding of the interactions between these strategies in terms of grinding wheel wear mechanisms and material separation for lateral side grinding. The objective of this research project is therefore the fundamental understanding of the grinding wheel conditioning, the abrasive grain kinematics as well as the cumulative number of active cutting grains. This research project will investigate the effect of the input parameters on the grinding wheel wear mechanism and cutting insert quality during transverse side grinding.