Ultra-precise positioning of workpieces due to hovering guidance system

| Led by: | Prof. Dr.-Ing. Berend Denkena |

| E-Mail: | Tasyuerek@ifw.uni-hannover.de |

| Team: | M. Sc. Derin Tasyürek |

| Year: | 2023 |

| Funding: | DFG |

| Duration: | 07/2023 – 07/2025 |

In ultra-precision machining, components are produced with sub-micron tolerances and surface finishes. The scaled variations of conventional macro-manufacturing concepts, however, come up against limits as they are affected by interference effects such as friction and stick-slip effects.

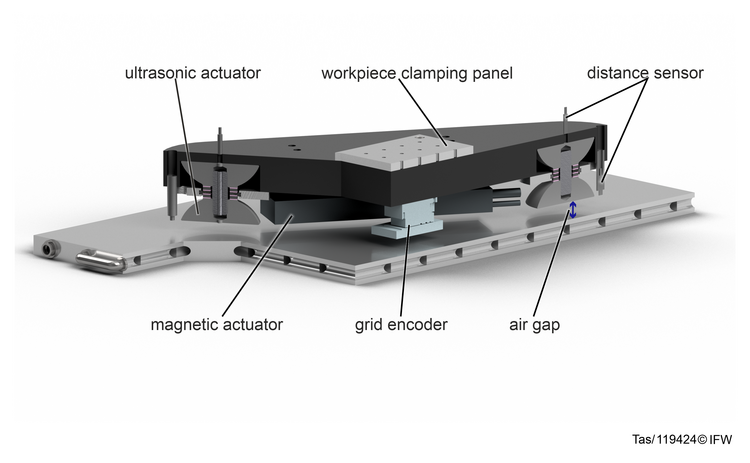

The DFG project "Media-free and contactless multi-coordinate positioning system using ultrasonic levitation and magnetic guides" is investigating a novel guidance system that combines ultrasonic levitation and magnetic guides (ULM guidance). This enables frictionless, precise guidance of workpieces and tools. The ULM guide raises the carriage of the guide system through an ultrasonically generated air cushion and uses magnetic actuators for stabilisation. The technology provides control over three degrees of freedom - roll, pitch, lift - and offers increased rigidity compared to, for example, aerostatic bearings.

The ULM guide offers the advantage of a contact-, media- as well as wrap-around-free guide, which reduces the technical complexity and the installation space. The system's low compliance of less than 50 µm/kN shows the potential for precision manufacturing applications.

Contact:

For further information, please contact Derin Tasyürek, Institute of Production Engineering and Machine Tools (IFW) at Leibniz Universität Hannover, by phone +49 511 762 4607 or by e-mail at tasyuerek@ifw.uni-hannover.de.