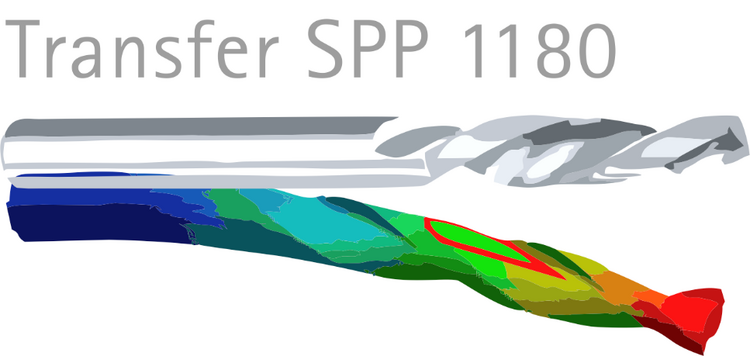

Knowledge transfer project SPP 1180: „Effective process design for tool grinding in consideration of the process-structure interactions“

| E-Mail: | wichmann@ifw.uni-hannover.de |

| Year: | 2017 |

| Date: | 16-01-17 |

| Funding: | DFG |

| Duration: | 01.01.2017-31.12.2018 |

| Is Finished: | yes |

There is a conflict of objectives in the tool manufacturing between the increasing number of individually designed drilling and milling tools and the increasing cost pressure. In the manufacturing process of slender components with a large overhang, the interactions between the process and the workpiece create shape deviations. Currently, these deviations can only be compensated by a high number of grinding experiments to adapt the axis infeed or efficiency-reducing measures, like a support of the tool blank. Based on the findings of the basic research project DE 447/57 from the priority program 1180, this transfer project develops a method for the model-based design of individual tool grinding processes and investigates it in an industrial environment.

Within the method, a simulation-based optimization of the tool grinding process ensures compliance with the required manufacturing quality. As a result of the project, the required number of tests and the need to support the tool blank is significantly reduced by considering the process-structure interactions during process design.

The innovation of the model-based design approach is that a numerical analysis precedes the previously experimental verification of a newly designed grinding path. The grinding path is geometrically simulated with the corresponding process parameters and indicated by characteristic variables, like the specific material removal rate Q'w, the contact length lg and the equivalent chip thickness heq. These characteristic variables are used for comparison with reference processes. If certain limit values are exceeded, the parameters are adjusted and a new geometric analysis of the process is performed. After successful adaptation, the process forces and the resulting shape deviation are determined. In case of process behaviour outside the tolerances, the results lead to an adaptation of the grinding paths or, if the required tolerances are reached, to the end of process design.