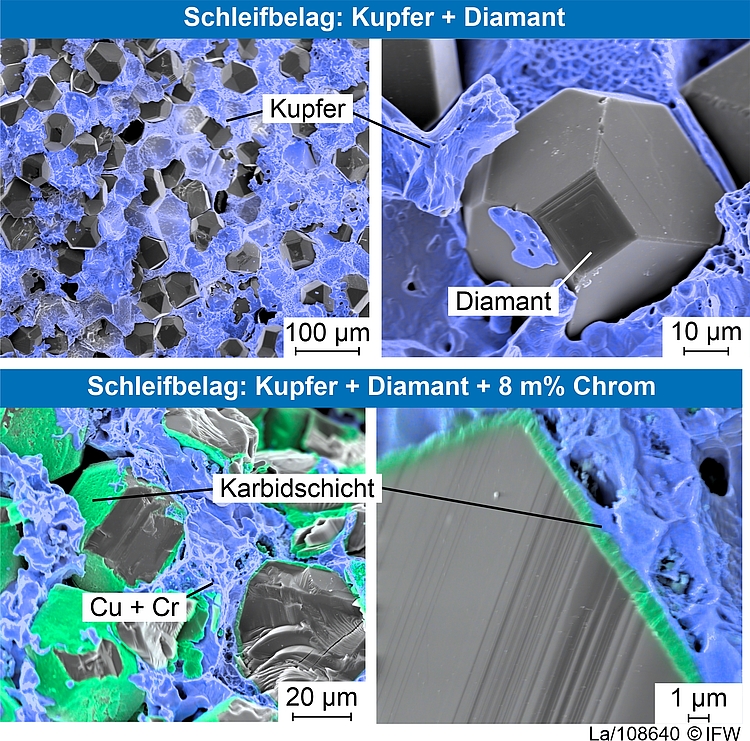

Application behavior of sintered metal diamond grinding wheels with chemically bonded abrasive grains

© La/108640©IFW

© La/108640©IFW

| Led by: | Prof. Dr.-Ing. Berend Denkena |

| E-Mail: | Lang@ifw.uni-hannover.de |

| Team: | Roman Lang |

| Year: | 2022 |

| Date: | 02-08-22 |

| Funding: | DFG |

| Duration: | 07/2020 – 07/2023 |

Metallically bonded diamond grinding wheels usually use a bond system based on copper or bronze. A chemical bond, e.g. by forming a carbide layer between the bond and the diamond, has the potential to increase the grain retention forces and the wear resistance and thus to improve the performance of the grinding wheel. Process parameters during the sintering process, as well as the composition of the bond system used, play a significant role in the bonding of the diamonds to the bond matrix. An addition of chromium to the copper bonding matrix not only increases the grain retention forces, but also significantly increases the thermal conductivity of the abrasive coating.

The aim of the project is to determine mechanical and thermal characteristic values on the basis of dynamic and static investigations on the previously manufactured diamond grinding wheels with chemical bonding and to use these for the creation of simulation models. The simulation models created will make it possible to observe the temperature distribution within the abrasive coating as a function of the manufacturing parameters. In addition, the knowledge gained about the mechanical parameters is used to model and simulate the macroscopic wear of the tool. By determining the workpiece temperature and the radial wear in grinding tests, the created simulation models are validated.