Investigation of the function of a new type of milling tool designed for roughing and finishing operations

| E-Mail: | ellersiek@ifw.uni-hannover.de |

| Year: | 2018 |

| Date: | 15-03-18 |

| Funding: | DFG |

| Duration: | 07/17 - 30/06 |

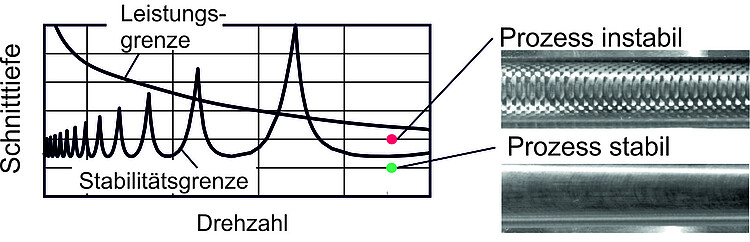

The aim of this project is to design a milling concept that combines the advantages of roughing and finishing tools. In roughing, productivity is the most important goal. This is, in addition to the power limit of the machine tool, limited by the occurrence of self-excited vibrations, so-called chatter. The occurrence of these vibrations can be counteracted by flank face chamfers. As a result, the flank face gets in contact with the surface of the workpiece and squeezes it. The resulting force has a dampening effect on the process and chatter can be suppressed. On the other hand, the finishing ability of a tool is largely determined by the quality of the surface produced. However, flank face chamfers result in burrs and rough surfaces due to material squeezing and are therefore not suitable for use in the finishing process. The idea of the tool concept examined in this project is to be able to use the damping effect of the flank face chamfer also in the finishing process, in that two chamfered cutting edges are set back radially and thus do not get in contact with the final surface. This final surface is generated by two more sharp blades with a larger radius. The simultaneous use of sharp and chamfered cutting edges is investigated for both steel and aluminum. When designing the milling cutter, it must also be taken into account that the sharp cutting edges remove more material due to the larger radius and are therefore exposed to greater loads. This can be counteracted for example by an uneven tooth pitch. In terms of process stability an uneven tooth pitch can lead to improvements as well as deteriorations.