Non-contact aerostatic magnetic guide for machine tools

© IFW

© IFW

| Led by: | Prof. Dr.-Ing. Berend Denkena |

| E-Mail: | Blanz@ifw.uni-hannover.de |

| Team: | Jonathan Blanz |

| Year: | 2022 |

| Date: | 30-05-22 |

| Funding: | DFG |

| Duration: | 04/2022 – 10/2024 |

The purpose of a guide is to limit the movement of an element to movement in a single direction. Guides are used in machine tools to precisely guide tools and workpieces. In addition to conventional guides with rolling and ball bearings, there are also frictionless, non-contact guides. These are magnetic, aerostatic and hydrostatic guides. However, all of these guides have in common that they require a grip around the guide rail. A wrap-around leads to a larger installation space and very tight manufacturing tolerances. In previous research work on handle-free guideways, electromagnetic actuators were successfully combined with aerostatic bearings. This combination has made it possible to avoid the need for a handle, but the aerostatic bearings used place very high demands on the manufacturing accuracy of the guide surface.

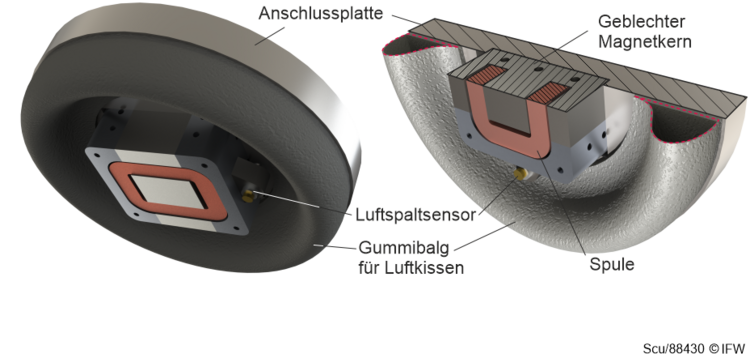

The new approach now being pursued is to combine an air-slide cushion with an electromagnetic guide. Here, too, there is no need for a handle, since the compressive forces are absorbed by the air-slide cushion and the tensile forces by electromagnets. By using the technology of the air-slide cushion, low requirements are placed on the guide surfaces. Air cushions are a proven technology that has been used for many years in industry to move heavy loads in industrial halls, but have not yet been used in machine guideways.

Through the selected combination and an active control of the electromagnet, the flight height of the guide can be influenced so that it is possible to compensate for unevenness in the guide surfaces. The lower demands on the guiding surfaces and the avoided circumference result in considerable cost savings.

Within the DFG-funded research project, an actuator for such a guide is simulated and experimentally investigated using the finite element method (FEM) and computational fluid dynamics (CFD). Challenges include, in particular, increasing the working pressure compared to the air-slide pads available on the market in order to improve the load-bearing capacity of the guide element and to avoid vibrations. Another focus is the precise control of the flight height of the guide in order to meet the requirements of modern machine tools.

The initial aim is to produce a functional model of a hybrid actuator for absorbing compressive and tensile forces of up to 4000N with a flight height that can be adjusted over a range of 0.5mm. In a further work step, a linear guide is to be constructed and evaluated from six actuators.