Load-optimized design of cutting edge microgeometries for industrial processes - DFG Knowledge Transfer

© IFW

© IFW

| Led by: | Prof. Dr.-Ing. Berend Denkena |

| E-Mail: | kraeft@ifw.uni-hannover.de |

| Team: | Malte Kraeft |

| Year: | 2022 |

| Funding: | DFG |

| Duration: | 01/2022-06/2024 |

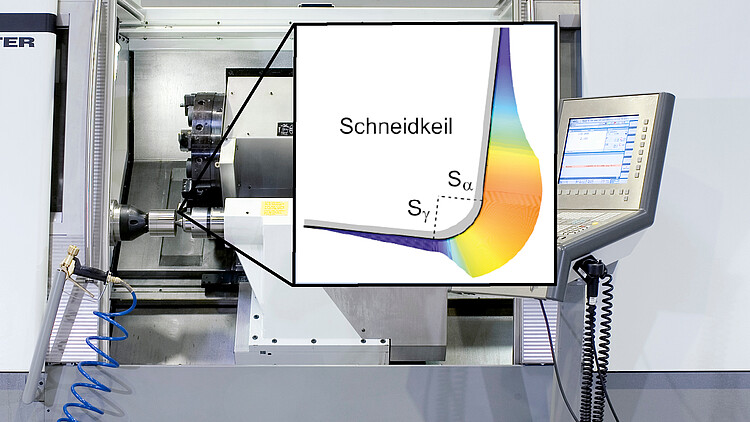

The cutting edge microgeometry significantly influences the application behavior of cutting tools. It therefore offers considerable potential for increasing productivity and process reliability. For maximum performance, the microgeometry of cutting tools must be adapted to the material to be machined and the loads present during use. The great potential of cutting edge rounding has so far been demonstrated in orthogonal and external longitudinal turning. For the application partner MAPAL Dr. Kress KG, internal longitudinal turning (hereinafter referred to as internal turning) and kinematically identical boring in particular represent relevant application fields, which are characterized by deviating contact conditions (effective rake and clearance angle) and loads. The application of load-optimized fillets for these processes offers considerable potential for increasing tool performance. However, for a broad industrial coverage of the boundary conditions of these processes, knowledge regarding interrupted machining and wet machining as well as the influence of deviating tool macro-geometries is missing. Furthermore, there is no generally valid knowledge and design methods for the preparation process to create specific fillets. Therefore, the underlying knowledge from the projects DE 447/71-1 and DE 447/71-2 shall be applied and extended in order to enable a load-optimized design of the cutting edge microgeometry as well as an efficient production of these for internal turning and boring.